About the project

Sustainability is on everyone's lips - and rightly so.

But what does this mean for the design process?

Flow of goods, transport load, manufacturing, material expense, operating expense, material separation, recycling, reprocessing, disposal.

What does the legislator say, what do the standards say on the subject? We researched.

How much is the sustainable production process already part of the lighting industry? We looked for examples and talked to manufacturers.

How strong is the desire for sustainable luminaires among users? We asked and sketched the mood.

How much do existing databases help us assess environmental impact? We provided access and got the picture.

The class researched and compiled information, evaluated and weighed in. Debated between long use and quick recovery, between complexity and simplicity, between the value of more and the consequence of less.

The result is a luminaire for the urban space or one for the workplace - for everyone and therefore relevant.

But what does this mean for the design process?

Flow of goods, transport load, manufacturing, material expense, operating expense, material separation, recycling, reprocessing, disposal.

What does the legislator say, what do the standards say on the subject? We researched.

How much is the sustainable production process already part of the lighting industry? We looked for examples and talked to manufacturers.

How strong is the desire for sustainable luminaires among users? We asked and sketched the mood.

How much do existing databases help us assess environmental impact? We provided access and got the picture.

The class researched and compiled information, evaluated and weighed in. Debated between long use and quick recovery, between complexity and simplicity, between the value of more and the consequence of less.

The result is a luminaire for the urban space or one for the workplace - for everyone and therefore relevant.

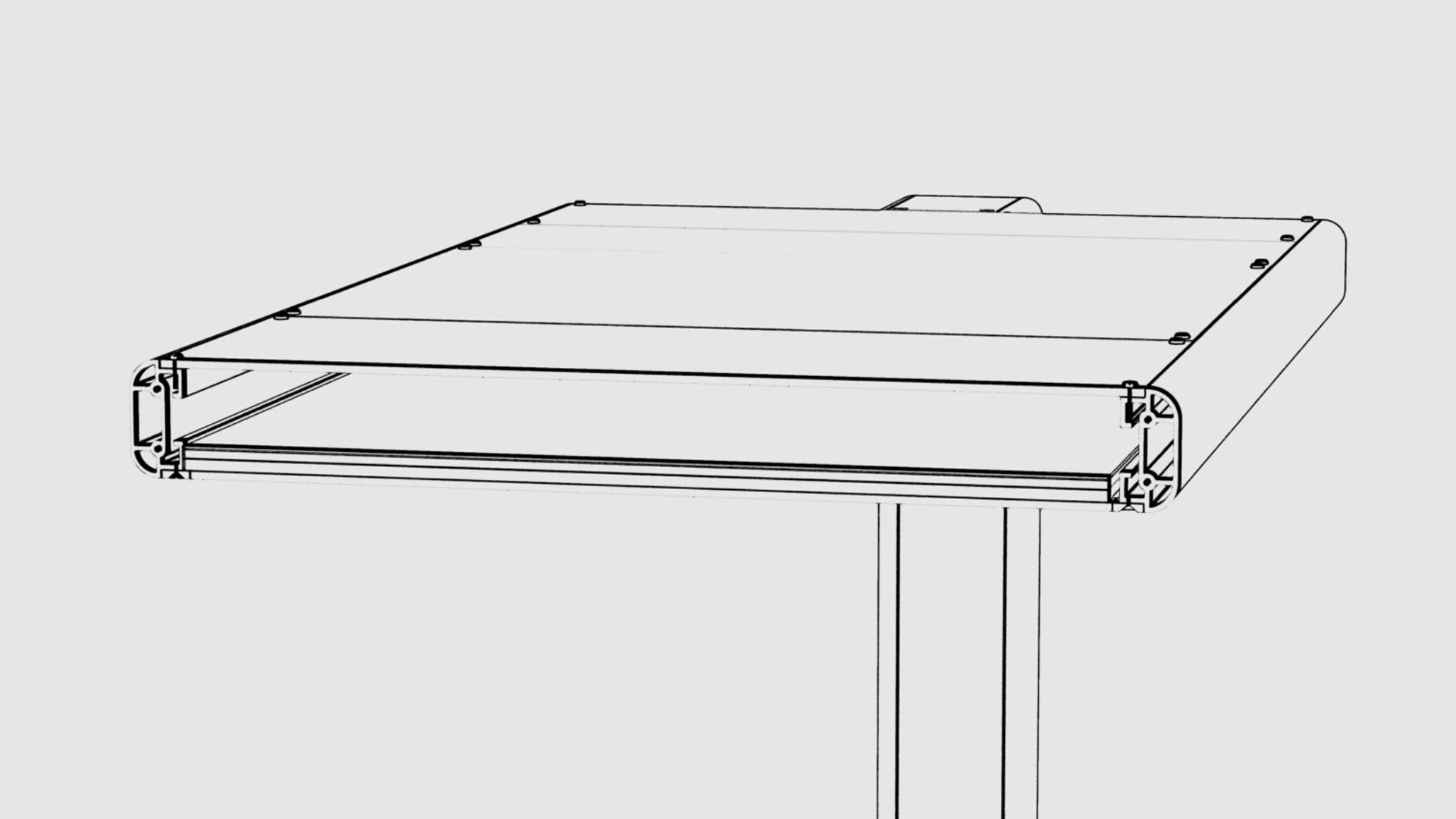

In the case of the "Kido" luminaire by Belux, the redesign approach is not to be understood as a revision of the aesthetics, but rather to question the current design process of the lighting industry.

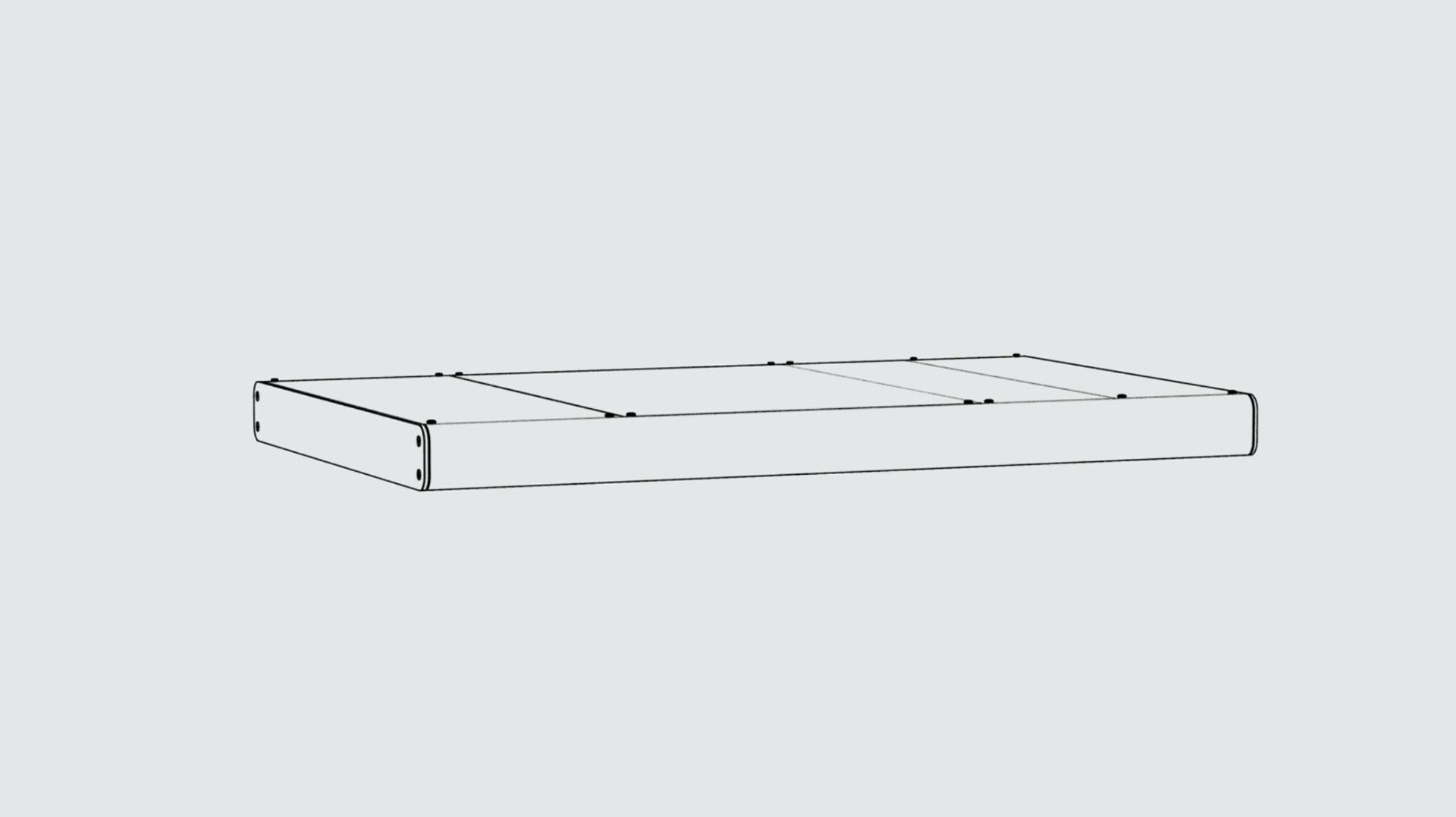

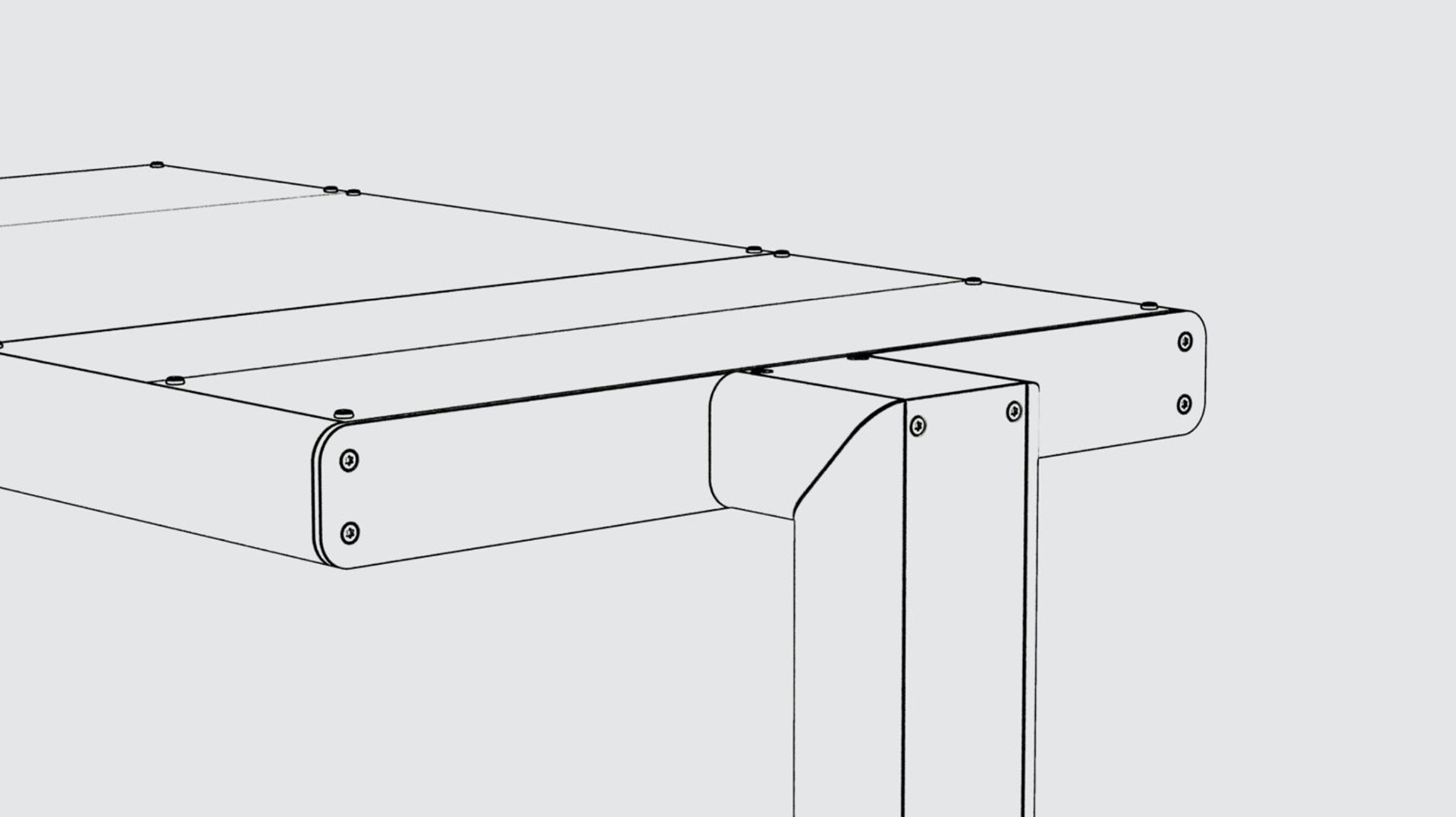

The focus of our design is on various aspects that should enable the greatest possible recyclability and sustainability of the product, irrespective of the choice of materials used. Thus, the design focuses mainly on the importance of optimized manufacturing processes, material savings, packaging possibilities and a complete dismantlability of the luminaire.

This approach is intended to provide food for thought for future design processes and to give the aspects of sustainability the same value as the aesthetics of the product itself.

The focus of our design is on various aspects that should enable the greatest possible recyclability and sustainability of the product, irrespective of the choice of materials used. Thus, the design focuses mainly on the importance of optimized manufacturing processes, material savings, packaging possibilities and a complete dismantlability of the luminaire.

This approach is intended to provide food for thought for future design processes and to give the aspects of sustainability the same value as the aesthetics of the product itself.

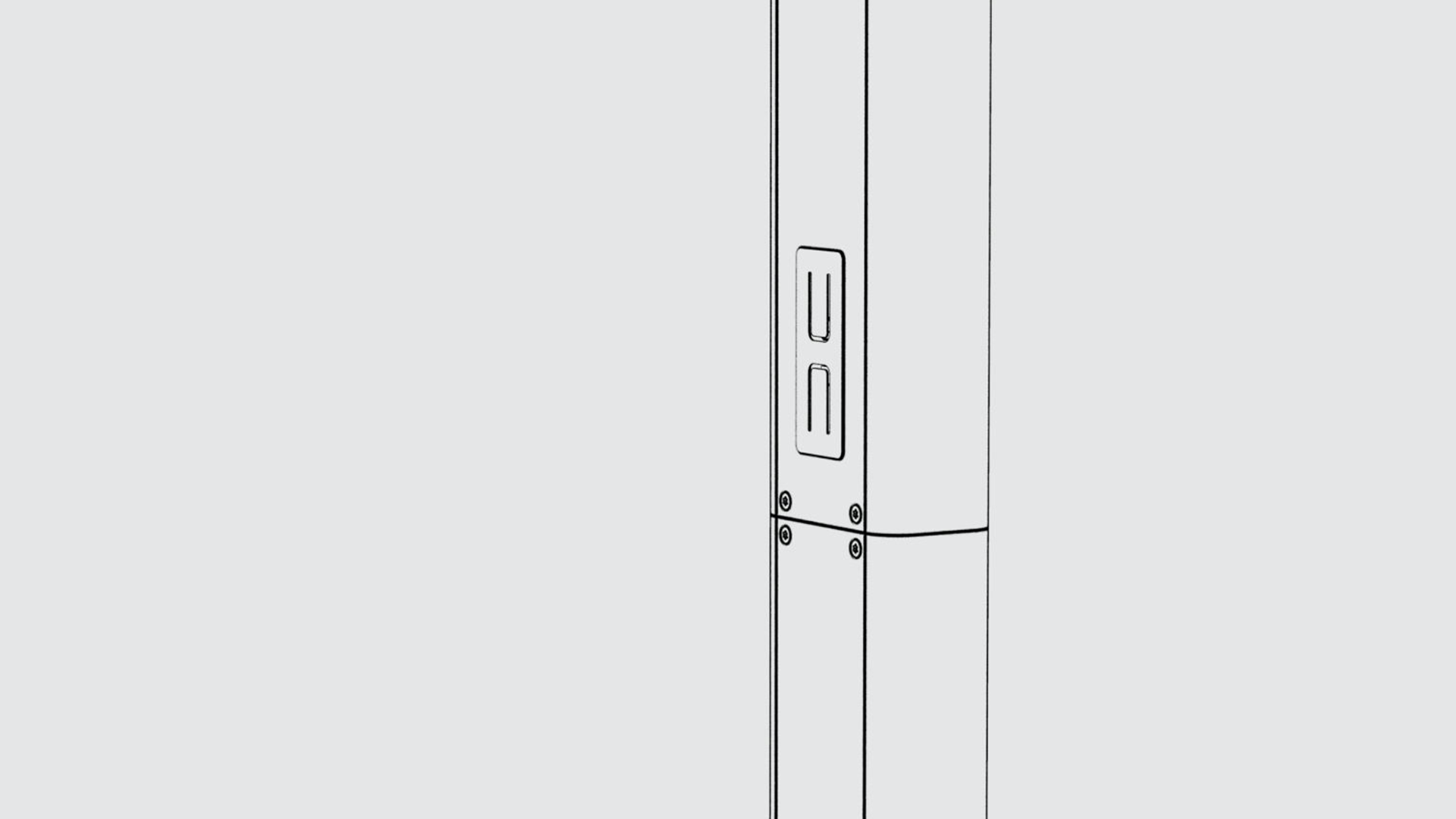

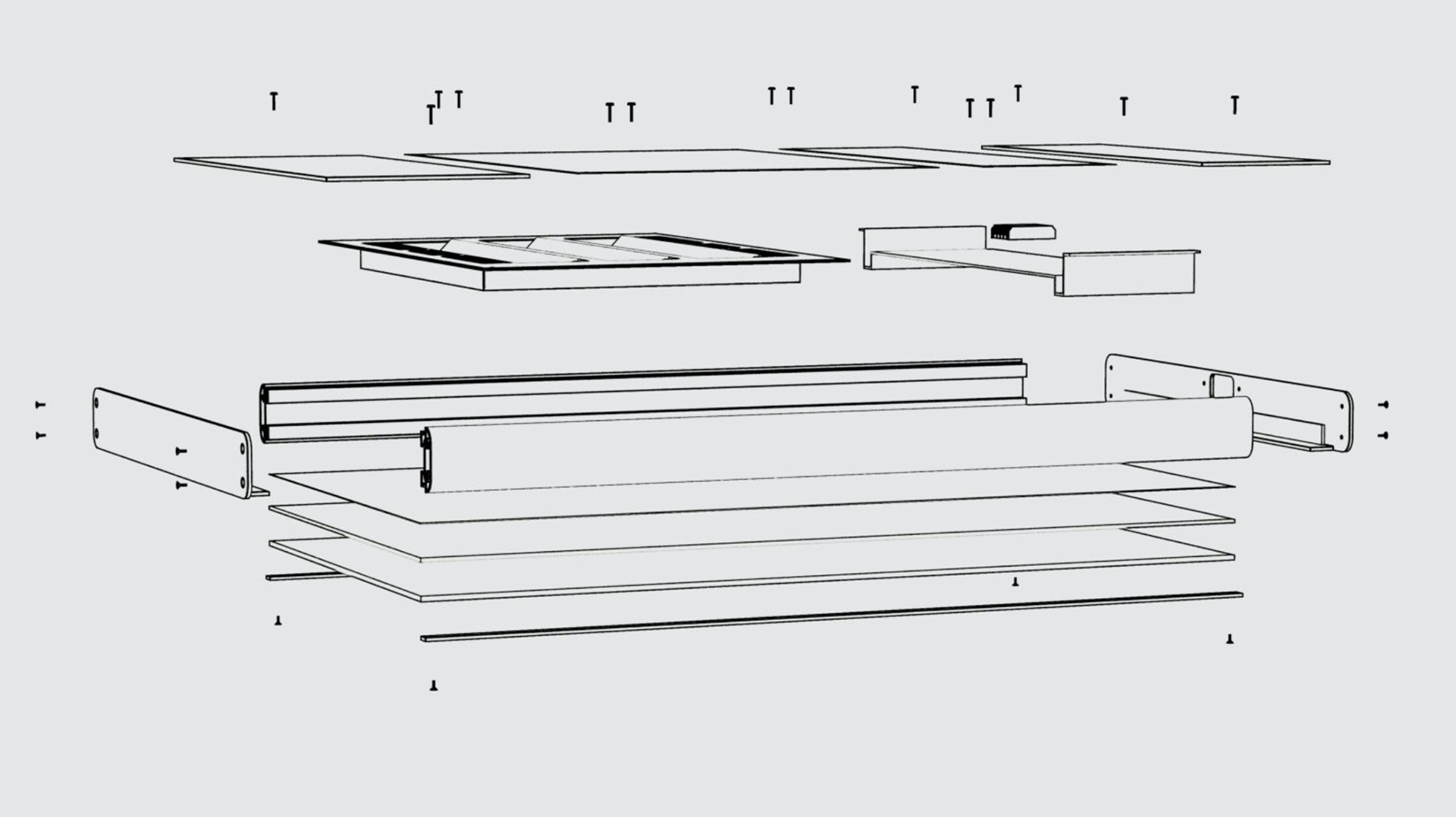

Components

Individual parts ReDesign

- 112 parts in total

- 64 of them screws

- two different types of screws

- countersunk head and round head Torx

- 64 of them screws

- two different types of screws

- countersunk head and round head Torx

single parts Kido Belux

- about 90 parts

- 39 of them screws

- 7 different types of screws

- 39 of them screws

- 7 different types of screws

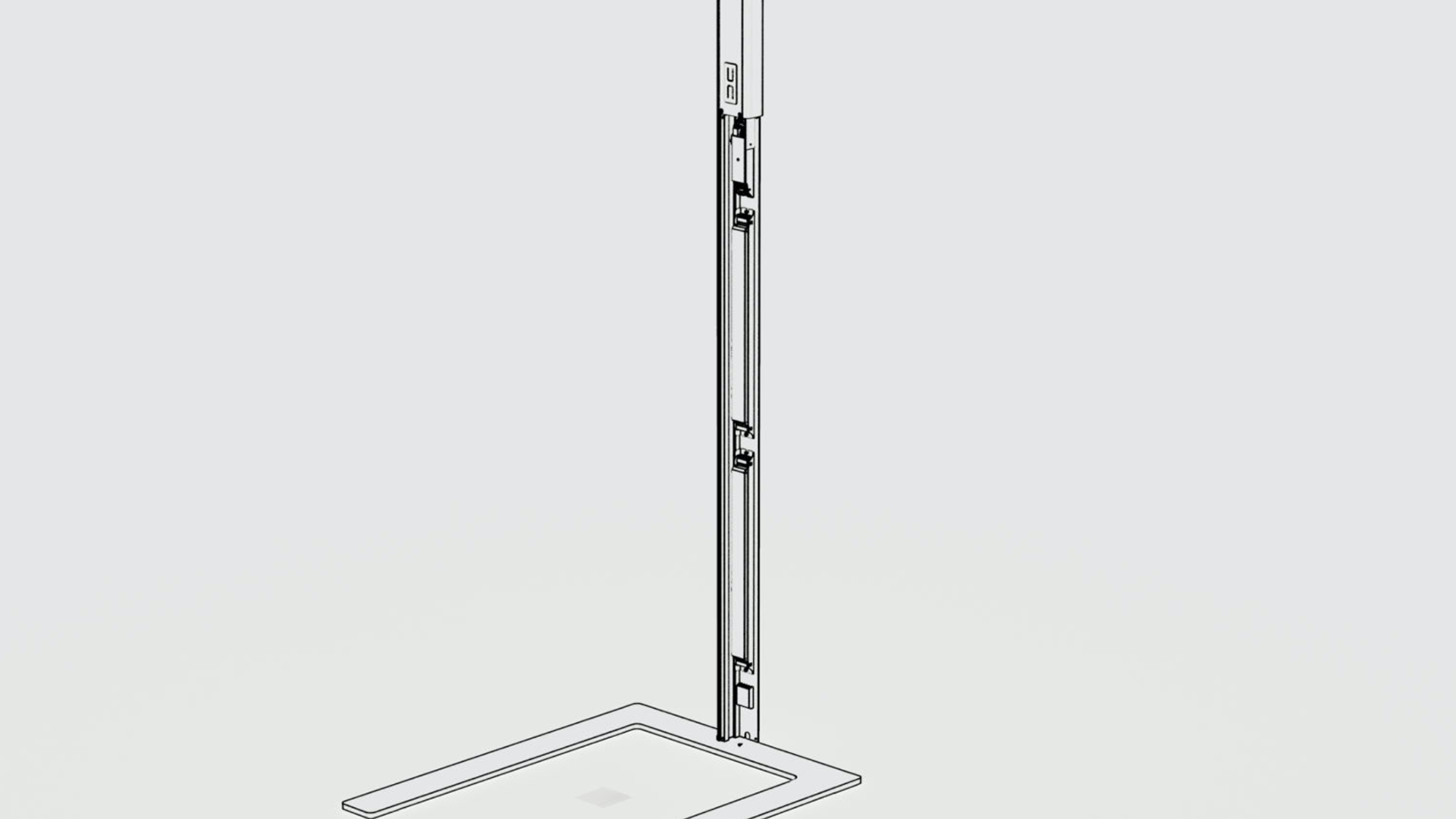

Flatpacking

Transport

- smaller packing due to two-stemmed bar

- different packing possibilities due to complete disassembly

- alternatively dismountable into four parts

- head, base and two-stemmed rod

- lamp head fits into the empty space of the base

- more sustainable transport due to space-saving packaging size

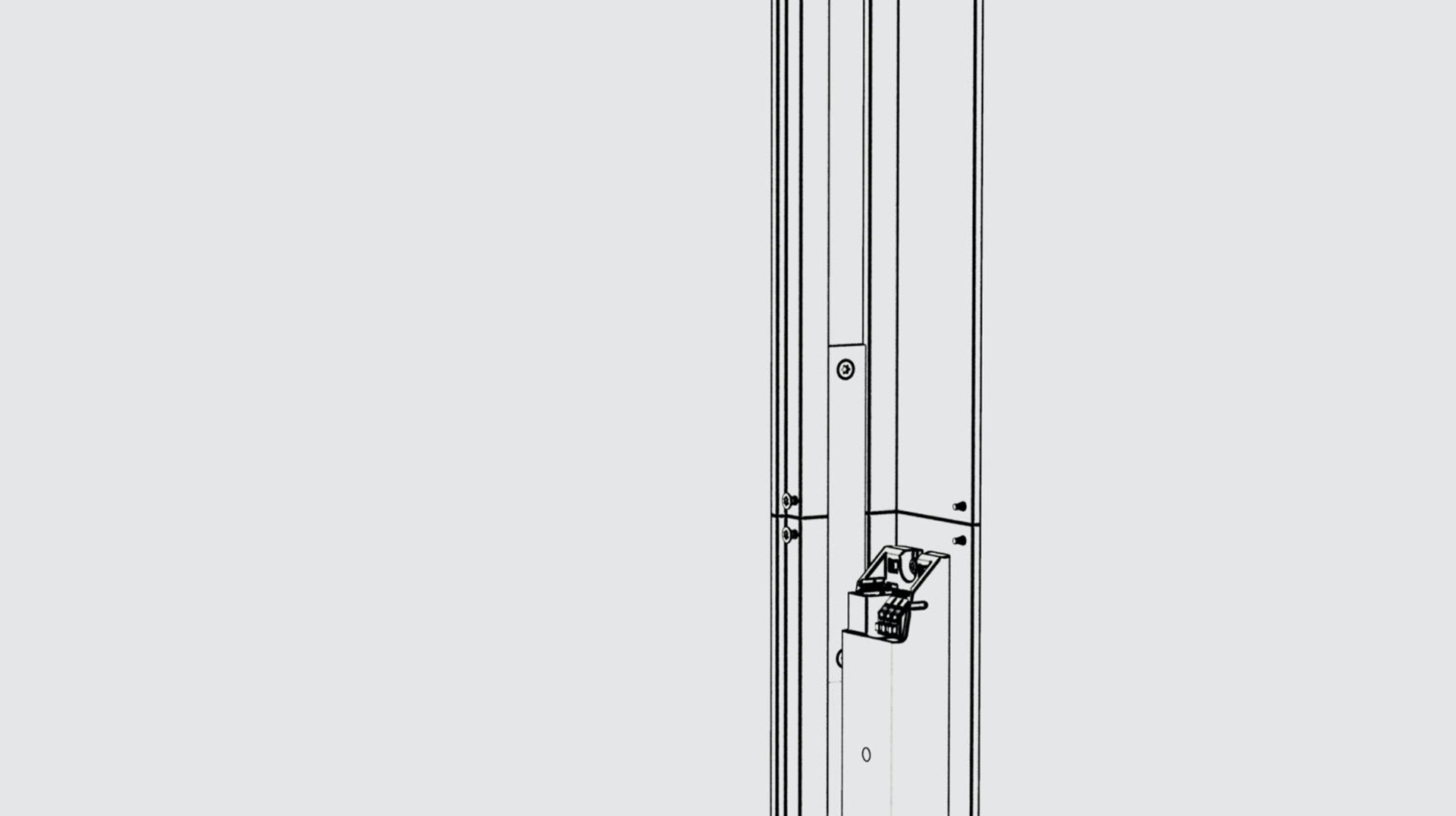

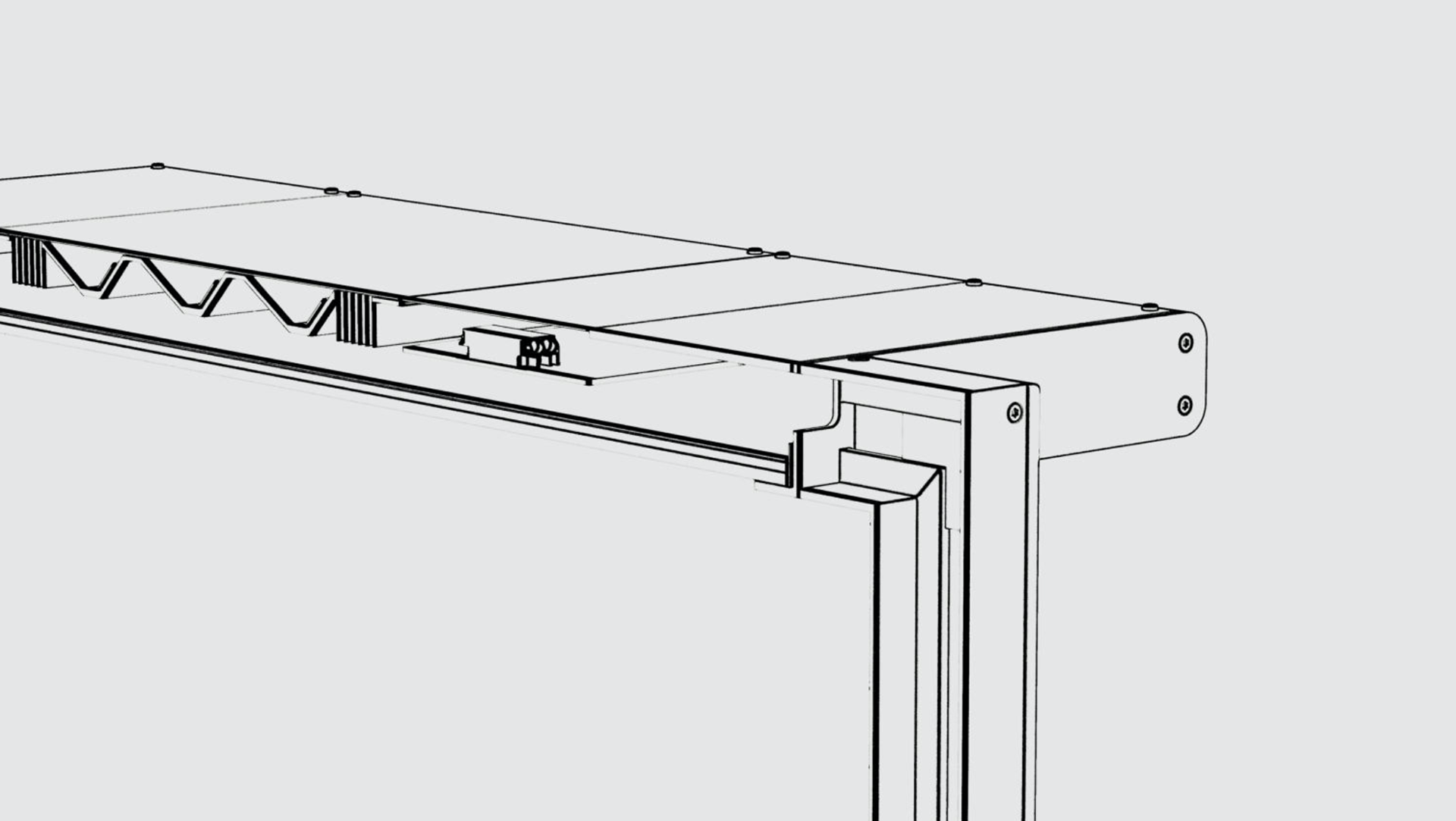

ReDesign lamp head

Profile

- profile of the rod also used in the luminaire head

- rectangular shape for less waste

- one plate saved as only 3-4% facing

- LED's on other side omitted, because no crucial benefit

- The design of a multi-use aluminum profile served as the starting point for the design of the luminaire

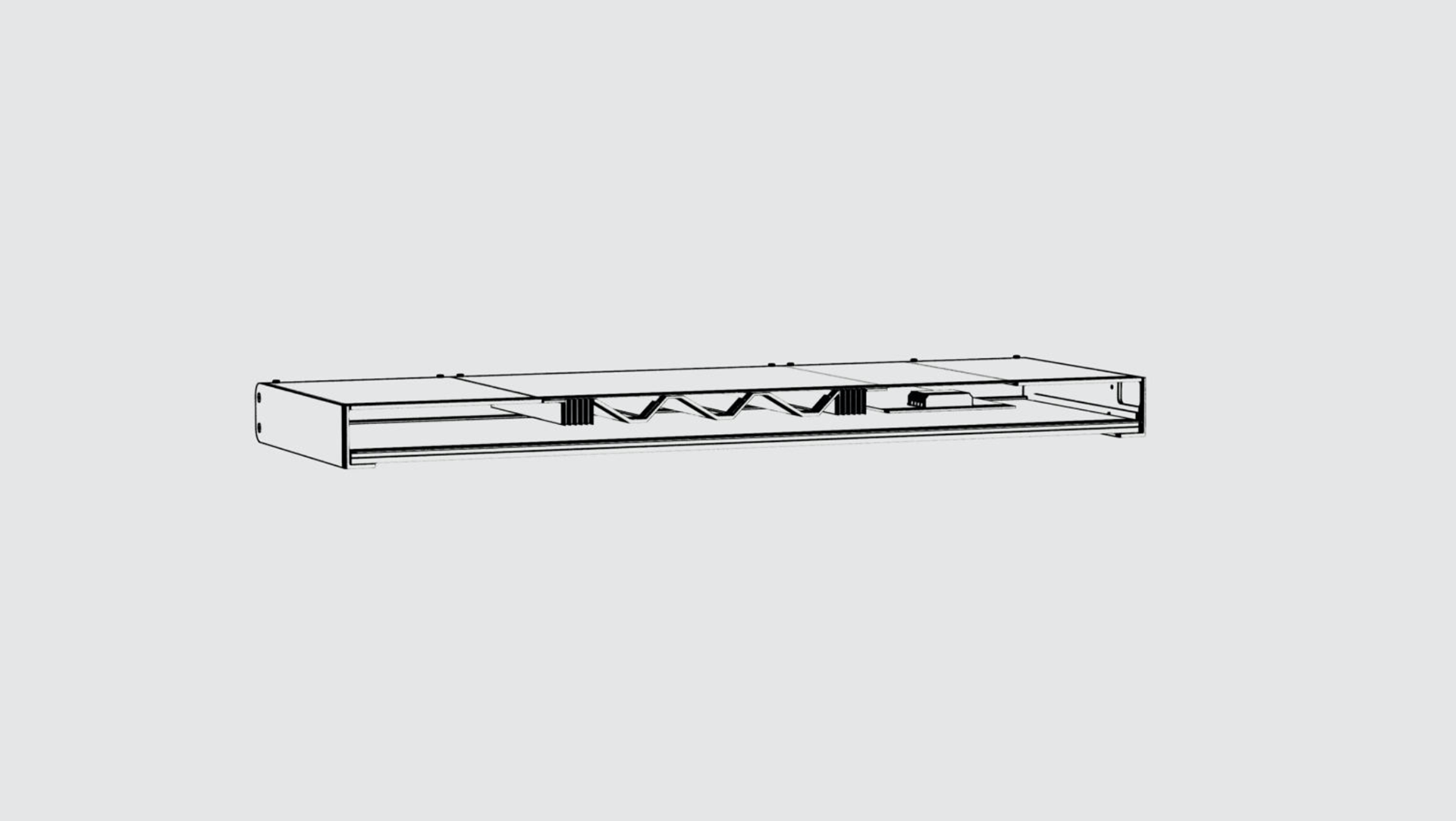

ReDesign

- very good reparability because it can be completely disassembled

- easy production due to bent sheet metal parts and profiles made of aluminum

- material and parts saved

- no welded parts

- all connections screwed